Stretch film is a highly versatile packaging material widely used across various industries for securing and protecting products. Known for its elasticity and durability, stretch film can wrap items tightly, ensuring that they are safely bundled and ready for transport. But what exactly is stretch film used for, and why is it a go-to option for businesses worldwide?

What is Stretch Film?

Stretch film, also called stretch wrap, is a plastic film primarily made of linear low-density polyethylene (LLDPE). It is designed to stretch up to 300% of its original size, which makes it perfect for wrapping products tightly without the need for additional strapping or boxes. Stretch film provides both protection and stability during shipping and storage, offering various benefits that make it indispensable in logistics and packaging.

Common Uses of Stretch Film

Stretch film is employed in a wide range of applications, particularly in the logistics, retail, and manufacturing sectors. Below are some of the most common uses:

1. Securing Pallets and Shipments

Stretch film is most commonly used to wrap and secure pallets. It prevents items from shifting or falling off during transportation. By wrapping a pallet tightly with stretch film, companies can ensure that multiple items stay bundled together, reducing the risk of damage during transit. This also helps maintain load stability for easier stacking in warehouses or trucks.

2. Product Protection

One of the key benefits of stretch film is its ability to protect products from environmental factors such as dust, dirt, moisture, and scratches. This makes it ideal for wrapping furniture, electronics, and other delicate items that need protection during shipping or storage. The stretch film’s transparency also allows workers to easily identify the wrapped products without removing the protective layer.

3. Bundling and Palletizing

Stretch film is used for bundling smaller items together before shipping or displaying them in stores. For example, cans, bottles, or boxes are wrapped in stretch film to create a compact and stable unit. This bundling method improves handling efficiency and reduces storage space requirements, making it easier to organize products in both warehouses and retail settings.

4. Cold Chain Packaging

In industries that deal with perishable goods, such as food and pharmaceuticals, stretch film plays an essential role in cold chain packaging. It helps ensure that products remain intact during freezing or refrigeration processes. Additionally, it prevents leakage or contamination, which is crucial for maintaining product quality and safety.

5. Protecting Palletized Goods from UV Damage

Stretch film can also come with UV-resistant properties, making it particularly useful for outdoor storage. This feature protects goods from harmful UV rays, preventing degradation of materials or discoloration of products when exposed to sunlight for extended periods.

Types of Stretch Film

Not all stretch films are created equal. Depending on the application, different types of stretch films are available:

- Pre-Stretched Film: This type is already stretched during manufacturing, providing high tensile strength while requiring less effort to apply.

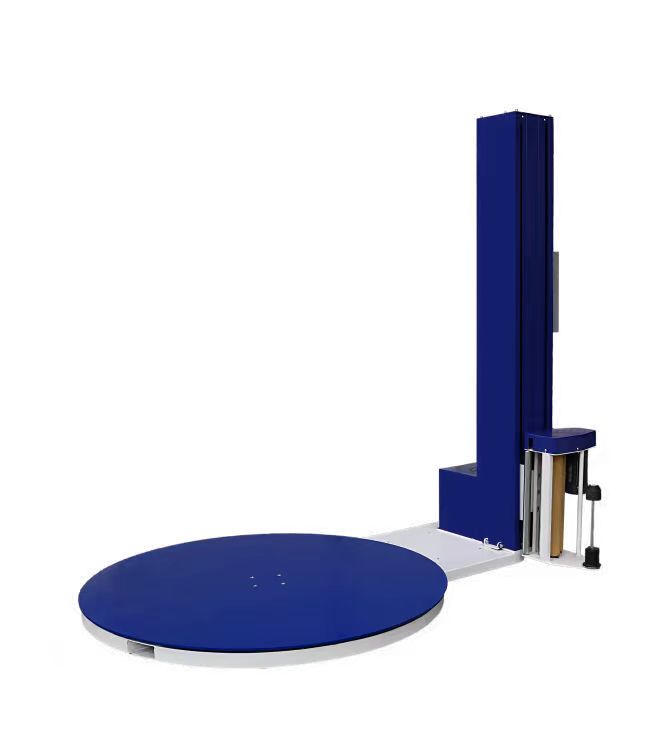

- Machine Stretch Film: Used in conjunction with a wrapping machine, this film is ideal for high-volume packaging in warehouses or production lines.

- Hand Stretch Film: Designed for manual wrapping, this is suitable for smaller shipments or operations without the need for a machine.

- Colored Stretch Film: Often used for branding or to differentiate products, colored stretch films also provide a layer of privacy and protection against theft.

Benefits of Stretch Film

Stretch film offers numerous advantages that make it the preferred choice for packaging. Some of its key benefits include:

- Cost-Effectiveness: Stretch film is typically more affordable than other packaging materials like boxes or corrugated cartons.

- Easy to Use: Stretch film can be applied manually or with a machine, making it adaptable to different production environments.

- Strong and Durable: The high stretch capacity and resilience of the material make it perfect for securing heavy or awkwardly shaped items.

- Environmentally Friendly: Many types of stretch film are recyclable, helping businesses reduce waste and improve their sustainability efforts.

Where to Use Stretch Film

Stretch film is used in nearly every sector where packaging and shipping are required, including:

- Manufacturing: To bundle finished products and prepare them for delivery.

- Retail: For packaging goods that are sold in bulk or need protection during handling.

- Warehousing: To secure items on pallets and optimize storage.

- Food and Beverage: For securing products in cold storage or ensuring sanitary shipping conditions.

Conclusion

Stretch film is an essential tool for packaging and protecting goods across various industries. Whether it’s securing pallets, protecting fragile products, or bundling items for shipping, stretch film offers versatility and strength. With its cost-effective nature and ability to provide reliable protection, it’s no wonder stretch film remains one of the most widely used materials in logistics and manufacturing.

For more information on packaging materials and their applications, visit Packaging Digest and International Packaging.

Keywords: stretch film, uses of stretch film, stretch film packaging, packaging solutions, pallet stretch film